Vintage Computer Equipment

Paper Tape .. & Editors!!

Introduction

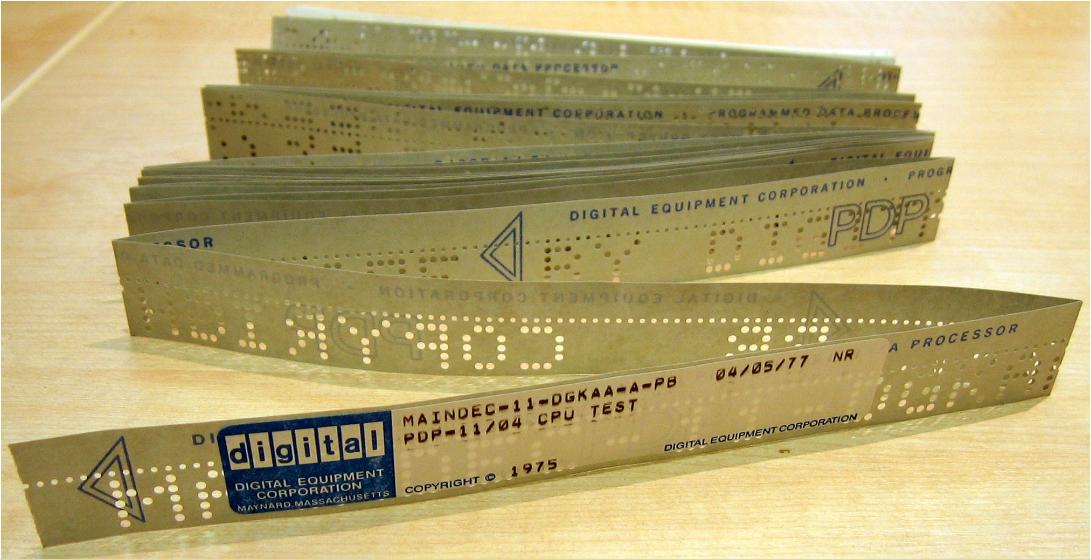

In the dim and distant past, well at least as far back as the 1960's and 70's, paper tape was one medium used to store and load

programs into computers. There are, for example; images on the web of a roll of paper tape which is an 8k BASIC for the Altair 8800

computer (1975).

In fact, paper tape was used even earlier than that, as the input medium to the COLOSSUS computing device designed and built at Bletchley Park in the UK in the early 1940's. Tape was read into COLOSSUS at up to 30mph; and there is a reconstructed COLOSSUS reading tape at 5000cps (characters per second) at the the National Museum of Computing at Bletchley Park. The teletype input tape was being read to decrypt messages encrypted by the Germans using their LORENZ machine for communciations during World War II.

The first picture belowto the right shows some 5 bit paper tape loaded onto spools on the COLOSSUS, and just to give a perspective of the size of the machine; the picture to it's right shows the paper tape assembly with a member of staff at Bletchley Park loading a tape onto the machine.

Computers and paper tape

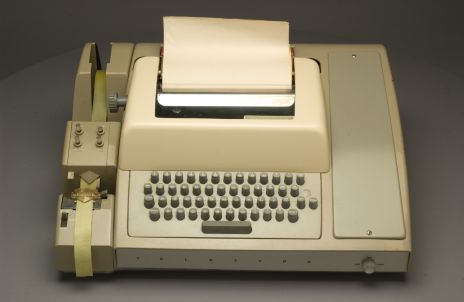

For computers, paper tape was regularly punched or read on Teletype ASR-33's such as the one shown below.

to the right. This was how I first experienced paper tape.

In this picture the roll of paper tape is in the slot at the rear left of the ASR-33, with the punch at the centre left and reader unit at the front left of the machine. The paper at the centre of the machine, is the roll of listing paper, where the typed characters were printed by the teletype unit.

The first programs I ever wrote in the early 1970's were on a Teletype ASR-33 using paper tape as the method of storage. The ASR-33 was

one of a number which were connected to a Data General Nova computer at Newcastle upon Tyne Polytechnic, (now Northumbria University).

Unlike COLOSSUS, the ASR-33 read and transmitted characters at a maximum of 10cps; 30 years on, but some 500 times slower!

Types of Paper tape

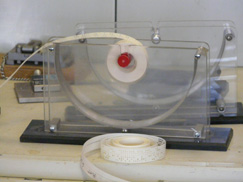

Paper tape was originally supplied as a roll, first picture below,

shown immediately to the right, then later as a fanfold format,

Paper tape basically came in two basic varieties, paper or Mylar. The Mylar variety was, I believe; paper tape sandwiched between two layers of plastic.

By the time I started to use paper tape, the format in use was 8 bits, although there have been variants in use with 5, 6 and 7 bits.

The picture immediately belowto the right shows two rolls of paper tape; one of which has been punched in 5 bit format, the other in the more recognisable 8 bit format.

How Paper Tape works

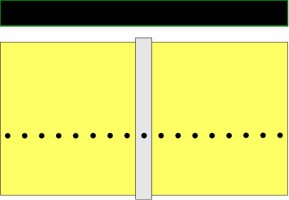

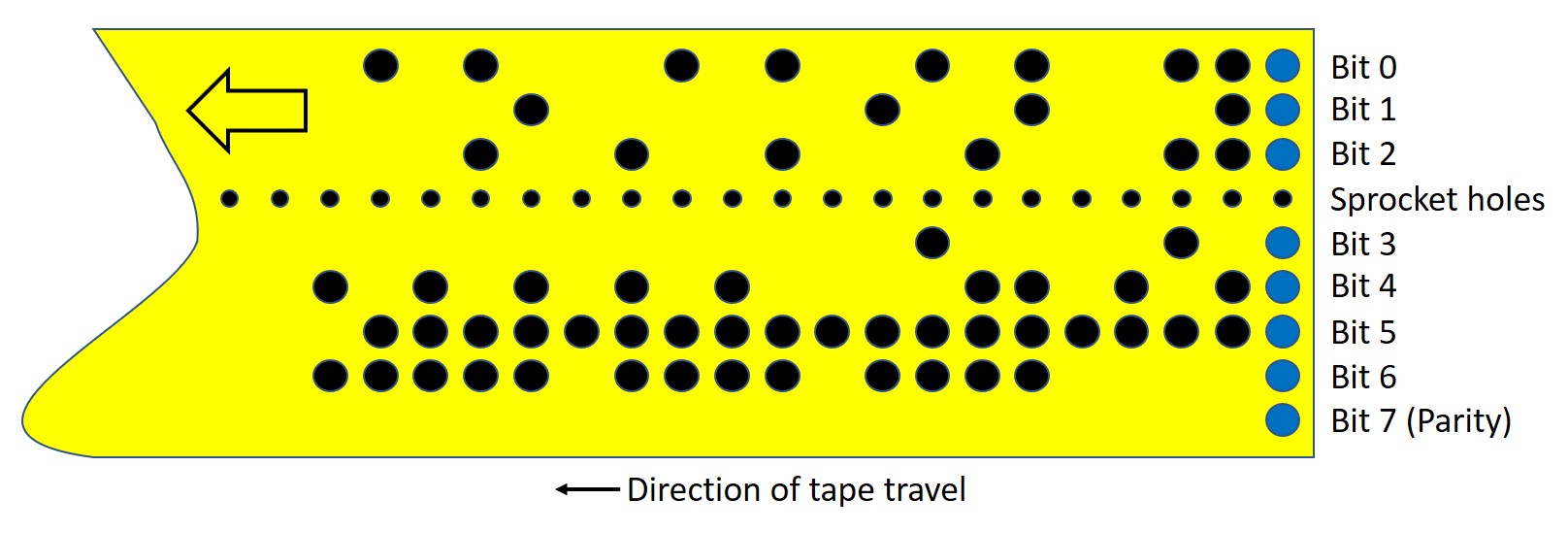

How does it work? Basically by shining a light source through a pattern of holes punched in the paper tape which corresponds to the

ACSII code for the desired character. Characters are read one at a time. The tape is advanced from one character to the next by using

the sprocket holes in the tape which are the continuous line of small holes just below the centre of the tape, as shown on the right.

The image belowon the right is an animation to show paper tape in use. The black window at the top is where the characters which have been read will appear. The vertical grey bar represents the optical reader. As the tape progresses from right to left, the punched holes in the tape will be read as they pass under the reader. The read holes are shown in red. As each character is read, it is displayed in the window above. A very basic animation, but it hopefully gives an idea of paper tape in action.

How big were the programs?

It obviously depends on the complexity of the program, but as there were computers running chemical plants which had only 16kB of

memory

YES, 16kB. However, the program would be significantly smaller than that as there was also real time data to collect and store in the memory as well.

On the chemical plant where I worked, there were a number of process control computers with 24kB of memory where the program was

loaded by paper tape. The operators controlled the plant by typing at a teletype, like the ASR-33 shown above. Critical information

was displayed to the operators by printing it on the paper roll.

Windows? What Windows? Eat your heart out Bill Gates!

How was/is paper tape loaded?

Good question! It depends on the type of paper tape, roll or fanfold.

If it was in roll form, honestly, you would not believe how it was loaded. I worked on a chemical plant in the early eighties, and really, this is how it was done.

A pencil would be placed through the middle of the roll which would then be dropped into a plastic hopper like the one shown in the picture at the right hand side below.. The paper tape was then fed into a standalone reader on a table like the one shown in the picture on the left. As the paper tape passed through the reader (from right to left in the picture), it was collected in a 3 foot high plastic clothes bin which stood on the floor at the end of the table. Honestly!

Rewinding paper tape

Once the program was loaded, hopefully without it breaking, the paper tape was collected from the plastic bin and rewound using a gadget

like the one shown in the images below.to the right.

The end of the tape was placed into a slot in the small brown hub at centre of the left hand picture. You then turned the handle on the other side, bottom wheel in the centre image. While the tape was winding, you had to keep your hand against the paper tape to guide it onto the spool, sometimes getting paper cuts if you wound it too fast. The picture on the right shows a successfully wound tape.

Job done ... and I bet you think double clicking an icon to load a program in a few seconds is a real hassle!!

Loading fanfold tape

Program loading became much easier, however; with the advent of fanfold paper tape. The tape readers used had 'pockets' attached to them

to hold the paper tape about to be read, and to catch the tape that had already been read. The picture below

to the right shows an EECO TR9301 tape reader with the 'pockets' attached.

The paper tape program would be loaded into the right-hand pocket and the tape fed into the black reader in the centre. As the tape was read, it passed right to left to be folded neatly in the left-hand pocket, ready for re-use. Much easier than managing roll tapes!

Whilst the paper tapes were much easier to handle and significantly easier to use, they unfortunately snapped more often than the roll tapes due to the folds. Mylar tapes were more robust than the paper variety.

If a tape did happen to break during use, and this was more common with regulalry used diagnostic tapes, it wasn't the end of the world. All that had to be done was to repair the tape. But how?

Repairing paper tape

The principle of paper tape repair was the same as that used to repair cassette and reel to reel audio tapes using a tape splicer, with the

added funtionality that the program could be modified by using a stylus designed to punch extra holes in the paper tape if required.

If a paper tape snapped, it was repaired by applying patches which were either completely blank except for the sprocket holes, or fully

punched with all holes.

Patches were applied while holding the tape in a paper tape editor!

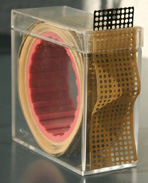

Sadly, I have neither tape nor patches left these days, however; the picture to the right shows a roll of fully punched patches inside a

dispenser box.

These are the very same sort of patches I used when I needed to repair snapped paper tapes.

Similar 'blank' patches were also available with only the sprocket holes punched. These were used when editing paper tapes.

Paper Tape Editors

Yes, there were such tools as paper tape editors. I know, because I have two and used them in the early to mid 1980's. The two editors that

I have, are shown and described below. I used the editors in the 1980's when I was a Control System Engineer for a company called Fisher

Controls. As an engineer I was predominantly involved in repairing process control systems, but also used to write software for chemical

plants.

The first machine I was involved with was an Interdata model 70 with 24kB of memory. Plant software was loaded and diagnostics

were run from paper tape. I also used to write small diagnostic programs which I converted into paper tape using a program called a 'Self

Loading Paper Tape Preparator'. This program created the necessary loader information at the start of the paper tape to enable it to be used

as a standalone program.

Which holes do I punch?

Ok, so you have a paper tape editor, perhaps similar to the ones shown below;

to the right; but how do you know which holes to punch in order to

modify your program?

Essentially, you need to know two things:

- Which hole corresponds to which bit

- ASCII codes

The picture below shows the which holes correspond to which bits in an ASCII byte. This format is the one I was used to.

5 bit paper tape such as that used in COLOSSUS, used a Baudot or Murray code, where all characters and some punctutation were represented

with 5 holes, rather than the 7 or 8 in what I would call standard paper tape.

The tape itself was 1" wide with the holes spaced 0.1" apart.